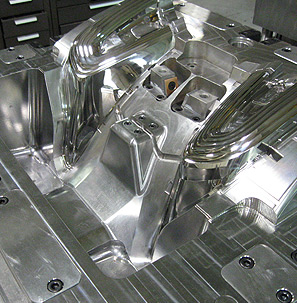

Injection Mold Design & Build of an Automotive Lens Part

Our mission here at Eagle Mold Co., Inc. is to provide value to our clients by building tooling that promotes the quality of the finished product, is easy to maintain, and matches the expected product lifecycle. We continually improve and expand our skill set in order to achieve an elevated level of ingenuity in our designs and enhance the precision of our workmanship. The injection mold highlighted here exemplifies how both of these efforts benefit our clients.

This tooling was used to produce components for an automotive tail light assembly. In the automotive industry, on-time production and delivery of robust, reliable products is vital given the fierce competition in this market. Our job as mold engineering specialists is to ensure that our clients produce the highest quality products possible at accelerated throughput rates and reasonable cost. Towards that end, we make sure we have the best resources for computerized mold design and process simulation, and the finest equipment available for achieving extremely close machining tolerances.

For this project, our engineers created a complex mold design that incorporated many moving actions, including core side and cavity side actions that were driven mechanically with the mold open. We also made sure the design was maintenance friendly to expedite servicing and ensure good finished part quality over its entire service life.

With their decades of experience, our skilled mold makers have a profound understanding of the challenges associated with precision tool making. They are constantly making innovations in our machining processes to create complex and detailed features. For this mold, they EDM machined the pocket for the core side drop away action at a compound angle to produce the as-designed geometries in the most precise way possible.

When completed, this mold measured 31" in length x 40" in width x 43" in height. Built from lens grade P20 steel to within close ±0.0005" tolerances, it featured an SPI A2 finish on the cavities. Despite the complexity, this project took us only 14 weeks to accomplish, and its first trial run produced parts that were completely on specification.

For more information about this project or our mold engineering capabilities, contact us today.

Automotive Lens Part Project Highlights

- Overall Mold Dimensions

- 31" X 40" X 43"

- Tightest Tolerances

- +/-.0005"

- Material Used

- Lens grade P20

- Material Finish

- SPI A2 finishes for cavity

Print This Page

Print This Page