Injection Mold Design & Build of a Multiple Valve Gated, Single Cavity Mold for the Bioscience Industry

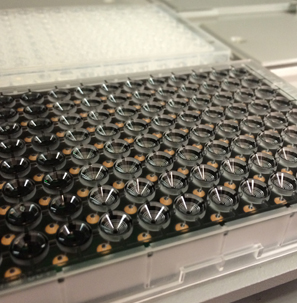

Building injection molds for small, detailed, tight tolerance parts is one of our core strengths here at Eagle Mold Co., Inc. Over the past 30+ years, we have kept up-do-date with new and emerging injection molding technologies and have a firm understanding of the very important role that tooling plays in the process. We designed and manufactured the single-cavity mold shown in the photograph to produce 96-well microtiter plates with dimensions of 3.5" in length x 5.0" in width x 0.5" in height.

In clinical and research laboratory testing, it is essential that microtiter plates exhibit a high degree of dimensional precision. Overall dimensions and well positions must be compatible with industry standards for microplate-based instrumentation to ensure the validity of test results. Manufacturers must produce these products with accurate and repeatable consistency in order to remain competitive.

For this project, we designed and built very precise and complex stainless steel tooling to ensure the accuracy of the footprint, height, and flange dimensions, well position, and well bottom elevation of this microtiter plate. The mold featured multiple valve gates to reliably control the flow of molten plastic into the mold cavity. Valve gating also allowed for a high degree of automation in the injection molding process as well as fast cycle times with a minimal amount of plastic waste. These attributes enabled the client to keep firm control over the costs associated with mass producing this product.

To construct the tooling, our technicians used a variety of processes, including high-accuracy milling and EDM machining to uphold tolerances of ±0.00015" on all mold features. One of the specific challenges was micro machining a fine surface finish. Detailed workmanship enabled our technicians to achieve the desired finish directly from the EDM, which was necessary because some of the cavity features were too small to access for polishing using standard methods.

Our client was very impressed that we were able to achieve a standard of excellence that none of their previous vendors had even come close to. The quality of the mold enabled them to attain very high yield rates and an extremely high-quality finished product. We continue to work with them on other programs.

If you would like more information about this project or our plastic injection mold engineering capabilities, contact us today.

Microfluidic ELISA Plate Project Highlights

- Overall Mold Dimensions

- 3.5" x 5" x .5"

- Tightest Tolerances

- +/-.00015"

- Material Used

- Stainless Steel

Print This Page

Print This Page